CIBRUSH 2025 to Highlight Synthetic Filiment Producer Cixi Jieda

Cixi Jieda, which focuses on deeply cultivating the nylon chemical industry, will exhibit its high-quality technology at CIBRUSH 2025, which will be held at the Shanghai New International Exhibition Center (SNIEC) on December 9-11, 2025. Jieda, which was established in 1988, has now formed three strategic business segments with high-end aggregation, advanced spinning, and global chemical trade as the core.

In the past forty years, Jieda has developed into a core manufacturer in the global civil and industrial brush filament field through continuous innovation breakthroughs and strategic investment, and has driven the continuous upgrading of the global nylon chemical industry with innovative polymerization technology, the company said in a statement.

Relying on a global sales and service network, Jieda said it “actively empowers the application expansion and high-quality development of cutting-edge fields such as new energy and new materials.”

Product Highlights include:

Nylon 610 and 612 Slices

Core advantage: Possess the core ability to independently polymerize and produce PA610 and 612 chips, and control the molecular structure and performance stability from the source; Relying on a stable raw material supply chain, we ensure the continuity and quality consistency of large-scale production.

Application value: Providing a reliable material foundation for high-performance bristles and precision components, supporting the performance upgrade of end products.

Abrasive Wire

Core advantage: Using nylon as the carrier, integrating multi specification grinding particles such as 16-3000 mesh silicon carbide, alumina, diamond, etc., through solid-liquid uniform blending melt spinning process, achieving uniform distribution of grinding particles in the silk body, ensuring wear resistance and grinding accuracy.

Application value: Widely applicable to scenarios such as steel cleaning, wood polishing, stone surface treatment, textile sanding, circuit board polishing, hardware polishing, LCD surface polishing, etc., meeting the full process requirements from rough polishing to fine polishing, it is a “precision tool” for industrial surface treatment.

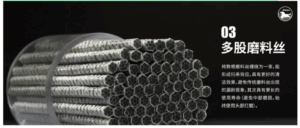

Multiple Strands of Abrasive Wire

Core advantage: Adopting an innovative structure of multiple abrasive filaments wrapped into bundles, forming a unique “broom effect”, effectively improving cleaning coverage and avoiding traditional single filament brush leakage problems; At the same time, through the “head priority wear” design, the service life is extended and the replacement frequency is reduced.

Application value: Targeting industrial cleaning and polishing scenarios with large or complex surfaces, improving operational efficiency and consistency.

Nylon 610, 612 Toothbrush Bristles

Core advantage: Made from self-produced nylon 610 and 612 as raw materials, the bristles have both softness and high elasticity, balancing cleaning power and gum care power; Among them, PA610 bristles contain 63.5% bio based raw materials, with outstanding green and environmentally friendly properties.

Application value: Suitable for high-end toothbrush products, achieving a user experience of “efficient cleaning, gentle gum protection, and long-term durability”, meeting consumers’ quality needs for oral care.

Nylon 12 Toothbrush Bristles

Core advantage: Made of nylon 12 material, it has excellent transparency and ultra-high softness, reducing irritation to the gums during brushing and improving user comfort; At the same time, the low water absorption and low density characteristics ensure that the bristles are not easily deformed or prone to bacterial growth during long-term use.

Application value: Positioned in the high-end care market, providing exclusive solutions for sensitive gum populations and users who pursue a soft experience.

Sharpened Wire

Core advantage: Adopting a conical needle tip technology, the diameter of the bristles at the top is finer, which can penetrate into the gaps between teeth that are difficult for traditional bristles to reach, achieving precise cleaning; Sharp and rounded processing, balancing cleaning power and tactile sensation.

Application value: Suitable for deep cleaning toothbrushes, solving the problem of residual gaps between teeth, and improving the comprehensiveness and comfort of oral cleaning.

Industrial Yarn

Core advantage: Through customized process formulas, brush filaments can be endowed with multifunctional properties such as anti-static, UV resistant, high temperature resistant, and flame retardant; Provide cross shaped, hollow shaped, triangular shaped cross-sections to meet the cleaning and dust removal needs of different scenarios.

Application value: Covering multiple fields such as industrial cleaning brushes, polishing brushes, and household brushes, suitable for diverse working conditions.

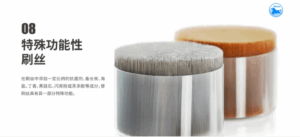

Special Functional Bristles

Core advantages: By adding functional ingredients such as antibacterial agents, prepared charcoal, sea salt, cloves, black silica, glitter powder, tea polyphenols, etc., brush filaments are endowed with added value such as antibacterial properties, odor absorption, fresh breath, stain removal, brightening, and visual decoration.

Application value: Meet the personalized needs of segmented scenarios, such as antibacterial toothbrushes, deodorizing cleaning brushes, beauty decoration brushes, etc., and expand the functional boundaries of brush filaments.

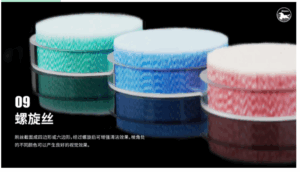

Spiral Wire

Core advantage: Adopting a quadrilateral or hexagonal cross-section design, forming a multi angular structure after spiral twisting, enhancing frictional contact with the cleaning surface, and improving cleaning efficiency; Different colors can be customized at the corners to enhance visual recognition and increase the attractiveness of the product’s appearance.

Application value: Suitable for scenarios that require both cleanliness and aesthetics, such as home cleaning brushes, beauty tool brushes, etc., balancing practicality and design sense.

Copper-Free Brush Wire

Core advantage: Based on the characteristics of copper free hair planting equipment, specific peak shapes and lubrication surfaces are designed to ensure smooth hair planting process, avoid equipment jamming and wire breakage problems, and improve hair planting efficiency and product yield.

Application value: Provide specialized bristles for copper free hair planting technology, adapt to automated production lines, and support efficient and precise brush manufacturing.

Learn more about CIBRUSH 2025, or to register, at www.cibrush.com.