Explore Cutting-Edge Trends at CIBRUSH 2025 With Yangzhou Meiyou Plastic Mold Co.

Yangzhou Meiyou Plastic Mold Co., Ltd. will exhibit its high-quality brush-making equipment at CIBRUSH 2025, which will be held on December 9-11, 2025, at the Shanghai New International Exhibition Center (SNIEC).

Yangzhou Meiyou Plastic Mold was founded in 2016 and is a technology enterprise that integrates precision mold research and development, manufacturing, and sales. It specializes in producing toothbrush molds and oral care product molds. The team’s years of professional experience in toothbrush mold design and manufacturing enable Meiyou to comprehensively and independently produce various complex and precise toothbrush molds. From product design, mold design, mold production to finished product delivery, as well as providing technical support to customers, to comprehensive after-sales service guarantee, Meiyou said it “always strives to create the maximum commercial value for customers.”

The company–located in Hangji Town, Yangzhou City, known as the toothbrush capital of China–has attracted customers in China, Spain, France, South Korea, Türkiye, Vietnam, India, Bangladesh, Pakistan, Indonesia, and Thailand. Looking to the future, it anticipates working together with new customers from all over the world to establish stable and successful business partnerships, and jointly exploring broader markets.

Introduction and Application Cases of Processing Equipment

1. Makino F5 High Speed Machining Center (Makino MAKINO) in Japan:

The Japanese Makino F5 high-speed machining center is used for the manufacturing of toothbrush molds. It can process various complex shapes with extremely high precision, ensuring consistency and quality stability between mold and product design. The high-speed spindle and rapid feed system, as well as the SGI.5 control system, make the machining process more efficient, enabling the rapid completion of toothbrush mold processing, shortening the mold manufacturing cycle, and thus improving the efficiency of the entire toothbrush mold production.

The Japanese Makino F5 high-speed machining center is used for the manufacturing of toothbrush molds. It can process various complex shapes with extremely high precision, ensuring consistency and quality stability between mold and product design. The high-speed spindle and rapid feed system, as well as the SGI.5 control system, make the machining process more efficient, enabling the rapid completion of toothbrush mold processing, shortening the mold manufacturing cycle, and thus improving the efficiency of the entire toothbrush mold production.

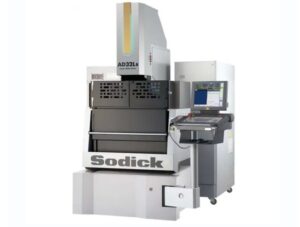

2. Japanese Shadick AD32Ls electric spark (Shadick Sodick):

The Japanese Shadik AD32Ls electric discharge machining machine is mainly used in high-precision mold manufacturing engineering in toothbrush manufacturing, especially for complex structures and surface treatment requirements that are difficult to achieve through traditional mechanical processing. Its core value lies in replacing some traditional mechanical processing and manual operations with electrical discharge machining, which not only improves product quality but also significantly reduces manufacturing costs and cycles, becoming a key equipment for manufacturing high-end toothbrush molds.

The Japanese Shadik AD32Ls electric discharge machining machine is mainly used in high-precision mold manufacturing engineering in toothbrush manufacturing, especially for complex structures and surface treatment requirements that are difficult to achieve through traditional mechanical processing. Its core value lies in replacing some traditional mechanical processing and manual operations with electrical discharge machining, which not only improves product quality but also significantly reduces manufacturing costs and cycles, becoming a key equipment for manufacturing high-end toothbrush molds.

3. Beijing Jingdiao JDCT600T Processing Center (Beijing Jingdiao):

The Beijing Jingdiao JDCT600T machining center is part of the precision machining project for toothbrush molds, mainly responsible for milling, drilling and other machining processes of the molds, providing high-precision molds for subsequent injection molding. It can stably achieve a processing accuracy of 5-20 μ m, with a dimensional accuracy of up to 10 μ m. It can accurately process key parts such as the cavity and core of the toothbrush mold, ensuring the external dimensions and structural accuracy of the toothbrush.

The Beijing Jingdiao JDCT600T machining center is part of the precision machining project for toothbrush molds, mainly responsible for milling, drilling and other machining processes of the molds, providing high-precision molds for subsequent injection molding. It can stably achieve a processing accuracy of 5-20 μ m, with a dimensional accuracy of up to 10 μ m. It can accurately process key parts such as the cavity and core of the toothbrush mold, ensuring the external dimensions and structural accuracy of the toothbrush.

4. Fanuc White T14iEe Drill Attack Center (FANUC):

When manufacturing toothbrush molds, the Fanuc Bai-T14iEe drilling center utilizes high-speed spindle and rapid feed technology, as well as shorter tool changing time, which can significantly shorten the processing cycle of toothbrush molds or components and improve production efficiency. High precision positioning technology and CNC system can ensure the machining accuracy of key parts such as the cavity and core of the toothbrush mold, as well as the dimensional accuracy and positional tolerance of toothbrush components, thereby ensuring the quality of the toothbrush.

When manufacturing toothbrush molds, the Fanuc Bai-T14iEe drilling center utilizes high-speed spindle and rapid feed technology, as well as shorter tool changing time, which can significantly shorten the processing cycle of toothbrush molds or components and improve production efficiency. High precision positioning technology and CNC system can ensure the machining accuracy of key parts such as the cavity and core of the toothbrush mold, as well as the dimensional accuracy and positional tolerance of toothbrush components, thereby ensuring the quality of the toothbrush.

Learn more about CIBRUSH 2025, or to register, at www.cibrush.com.