Interview: Wöhler’s New SBM 840 for Flex Trim

“You have to be able to make it easier — and better.” This thought came to carpenter Poul Erik Jespersen more than 25 years ago while he was bent over the hand sander at his workplace in a furniture company. The thought developed into an idea which, after a development period of eight years, became an internationally recognized and patented sanding system that is now sold worldwide.

The sanding system can be fitted to virtually any machine as long as the machine has an axis and a frequency-controlled motor to enable precise adjustment of the sanding speed. This means that the customer can generally use existing machines and can therefore avoid investing in new machines.

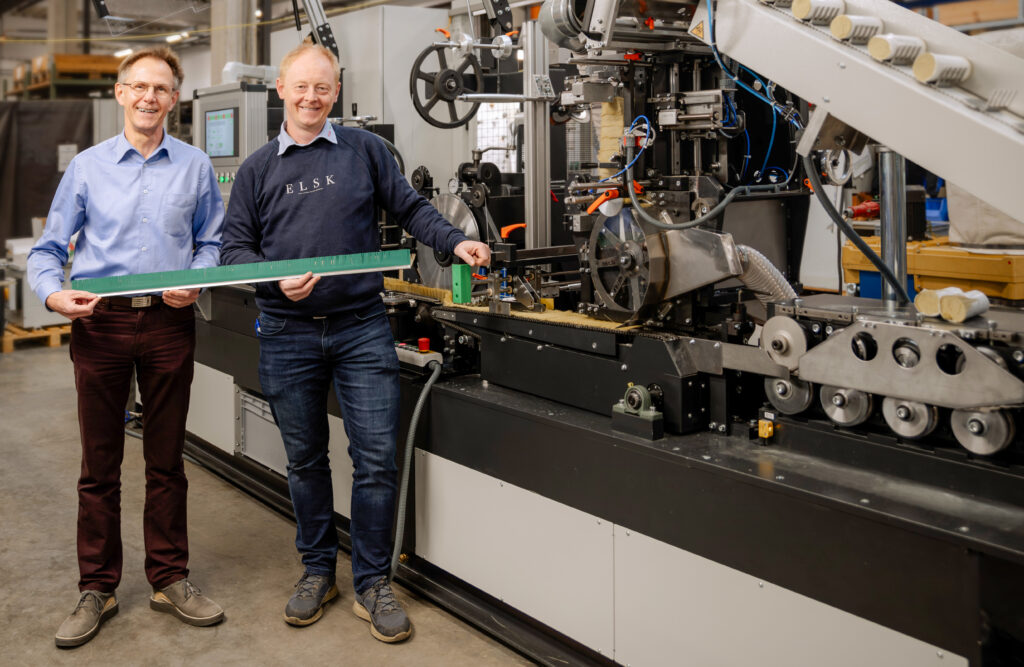

Flex Trim A/S from Denmark has been using an SBM 840 strip brush machine from Wöhler Brush Tech GmbH in Bad Wünnenberg, Germany, for the production of its exceptionally high-quality sanding brushes since 2008. In the midst of the coronavirus pandemic, Flex Trim decided to expand its production — convinced by the first machine, it had to be an SBM 840 from Wöhler Brush Tech. Wöhler sales manager Jürgen Tabert had a conversation with Karsten Larsen, sales manager at Flex Trim, about the reasons for the expansion and the decision in favor of another machine from Wöhler Brush Tech.

Karsten, how has Flex Trim developed over the past few years?

There has been a particularly positive development since 2017 — and then came corona. Despite corona, sales have continued to develop positively and we really made a lot more sales during the corona period. The world has also become smaller. Companies have become accustomed to holding meetings online. This has eliminated travel costs and made sales processes much more effective.

How has corona affected product development and new products for you?

We had more time to delve deeper into the various processes. This also allowed us to develop several new products. In addition, we were able to manufacture special products and special solutions that have made us more interesting for customers, particularly in the robotics industry.

How do your products differ from those of your competitors? What do your customers particularly appreciate about you and your products?

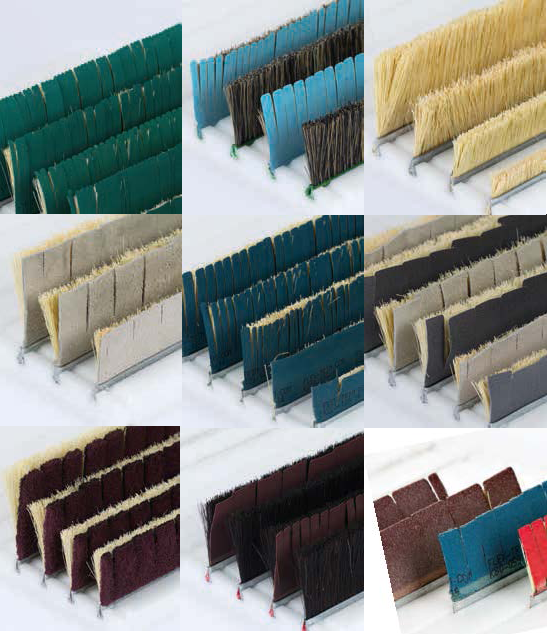

I think most customers see Flex Trim’s products as the market leaders — both technically and in terms of quality. Yes, our products have a slightly higher price, but the service life of our brushes is significantly longer than that of our market competitors. This means it is more expensive to buy, but you get a lower price per square meter sanded. Most customers say: “Yes, it’s more expensive if you have to buy it, but it’s much cheaper when you use it and the quality is very, very high.” And we are always able to deliver.

These are available in different lengths and diameters.

What outlook can you give for the future? Are there already developments as to how your business model or your products will change?

We have seen several new developments during the corona period. But we also get different requests than before. Customers need special products and special solutions for certain profiles or a specific burr that needs to be removed from a corner. We therefore supply more sanding processes and sanding solutions than just sanding products. This is why highly effective production processes that allow us to react and change over quickly are very important to us.

Are your order quantities changing? It used to be the case that people ordered as large quantities as possible in order to get price advantages. How is that developing for you?

This varies. For some standard applications, it is always the same, i.e. large quantities and a favorable price. But for special products, customers prefer to pay a higher price to find the right solution.

Some customers are confronted with ever smaller partial delivery quantities with the same total quantity over the year. What is your experience of this?

We are also experiencing this development. This is precisely why it is so important for us to be able to change our production quickly. So that we lose as little time as possible. Many companies have what I always call a stock anxiety. They don’t want to have anything in stock. And we have to adapt to that.

You have now purchased a new strip brush machine, an SBM 840, for the production of sanding brushes. Why was this new strip brush machine for sanding brushes necessary?

There were two reasons. We have had the first machine since 2008 and have never had any problem with it. Nevertheless, having only one machine was a risk. With two machines, we can react faster, have to change over less and can manufacture products more quickly. In terms of capacity, we don’t actually need the machine, but we want to remove the risk and that’s why we need another machine now.

Why did you choose a machine from Wöhler again?

We were satisfied with the first machine. We have never had a problem with the machine. We were and still are very enthusiastic.

That’s a wonderful statement, thank you very much! Were there any challenges in building this machine and the process that we were able to solve together and that were important to you?

The only challenge was the delivery time. Everyone knows that some components have been difficult to obtain in recent years and we were aware of that, but everyone also knows that when you buy or order something, you want it as quickly as possible. Basically, however, there was no problem.

However, a machine like this is not simply bought like a commodity, it is a very consultation and coordination-intensive process. How was the consultation and communication during the preparation and construction of the machine?

I think Wöhler would say that the decision-making process took quite a long time. After all, we received the first offer years ago. However, we only really realized how important it was for us to get a new machine during the corona period. Technically, there weren’t that many challenges. We already have a (similar) Wöhler machine that has been running for years. This means that Wöhler had experience in building such a machine. We have experience of working with a machine like this and the close collaboration meant it was actually quite easy. We both knew what we wanted.

sanding and backing materials.

We had discussed and developed different concepts together and then both independently returned to the tried and tested procedure, which was then optimized in certain areas.

Yes, exactly. What impressed me the most was the conveyor belt for the automatic bundle feed. Ergonomically, that’s a big plus for the employees. I think that’s really great and it’s a really good thing, where I say, okay, that’s a huge advantage for us.

Looking ahead now, what do you expect from development partners like Wöhler in the future?

Like us, Wöhler is a market and innovation leader in this industry. You have to keep that in focus. It will become increasingly difficult to find employees for such processes in the coming years. That’s why it’s important that Wöhler and other companies in this area think about how to make it as easy as possible for employees. To have as few manual processes as possible. You have to keep that in mind.

That’s something we hear again and again, the shortage of skilled workers, not just in Germany, but worldwide. In the future, the machine will have to take over many things that were previously done by skilled employees. And all this while production volumes are falling. So, it’s not a case of switching on today and switching off at the end of the month, but switching on this morning and switching to a different product at lunchtime. So, flexibility is definitely at the forefront. Karsten, thank you very much for the interview and we wish you a good production start and successful business with the new machine.

Thank you, let me put it this way: we have had the first machine of this type since 2008. We have more Wöhler machines, also because we are satisfied. That means 2008, now 2024 — we’ll meet again in sixteen years at the latest.

We will be happy to do so and then we will work together to overcome the predominant challenges and find the right solutions at that time. Thank you, thank you very much.

About the SBM 840

The Wöhler SBM 840 is a modular strip brush machine. It produces strip brushes with U-profile widths from 3 mm to 13 mm and fill lengths of up to 700 mm. Profile widths of up to 20 mm and Y-profiles are also possible as an option. Learn more about the SBM 840 at bt.woehler.com/machine/sbm-840/.