Boucherie Grateful to World Brush Expo Visitors

Boucherie extends its gratitude to all who visited their booth at the World Brush Expo in Bologna. The energy and the enthusiasm from visitors was a wonderful reward for the effort put into preparations for the show. It was great to spend time, talk business and leisure and have a beer and a bite with industry professionals. There was plenty to be seen and experienced in the booth:

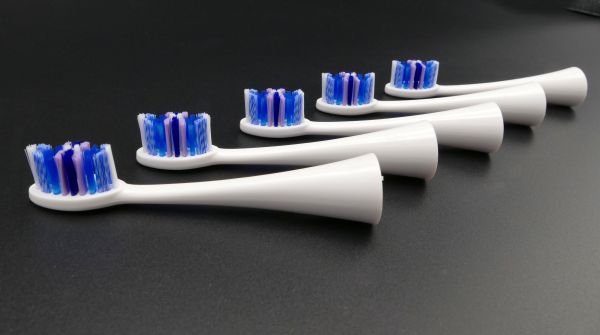

The Hepta-FM/R is a conventional toothbrush manufacturing machine, but it has a special tufting unit that will use plastic anchor plates instead of metal ones. This way, it is possible to make completely recyclable brushes, and by choosing the materials carefully, to make brushes that are completely made of one type of plastic.

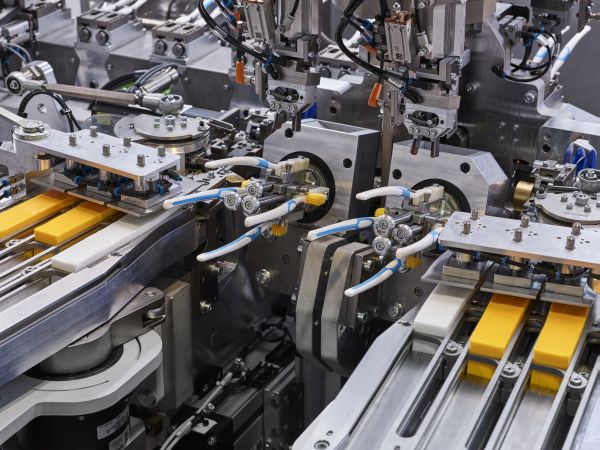

The PTt 2.0 machine for the production of anchorless toothbrushes had a complete upgrade with a new fibrebox, a faster filling tool and new tufting shuttles that will allow an output of up to 40 brushes per minute.

The Hepta-2-FM machine is a high-output toothbrush machine with two filling tools that each run at 1200 tufts per minute. It can be completely automated and gives the highest ratio of brushes per square meter of any machine available on the market.

The IDM machine for the production of interdental and mascara brushes is now available with a special spreading system for the filaments that give a much more consistent brush head, even when working with thinly spread very fine filaments. The output is up to 100 high-quality brushes per minute.

The AVT-E machine is a very simple and compact toothbrush machine for anchorless toothbrushes, with a very high output for its size. The machine can be automated, and will manufacture electrical toothbrush heads of high quality at a very high speed.

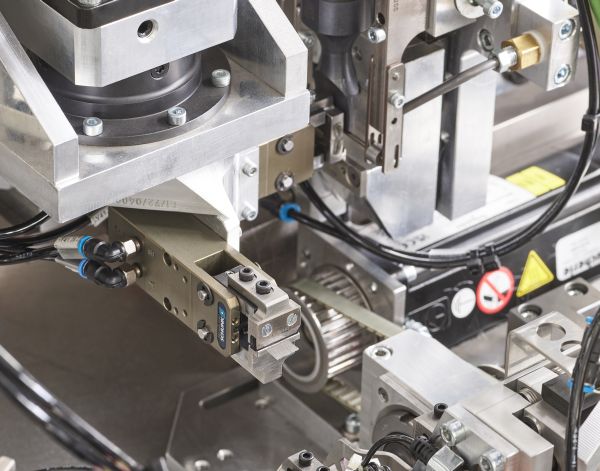

The FRM machine is a high-precision cutting- and endrounding machine for toothbrush filaments. It produces the pucks of endrounded filament that are used in the AVT machines.

The Illig range of packaging machines was presented as well : the HSU-35 is a compact and modular packaging machine for full-carton blisters. The HSU-650 makes full-carton blisters, and is fast enough to process the products coming from several tufting machines. For both machines, Boucherie builds automatic infeed systems to boost the efficiency even more.

Boucherie is grateful for the opportunity to connect with industry peers and showcase their latest innovations. The positive feedback and interactions at the World Brush Expo inspire continued excellence and innovation. Learn more about Boucherie at www.boucherie.com.