New Machine Launch From Roth Composite Machinery

Faster, More Flexible, More Sustainable: Roth Composite Machinery Launches Revolutionary New Machine for the Brush Industry

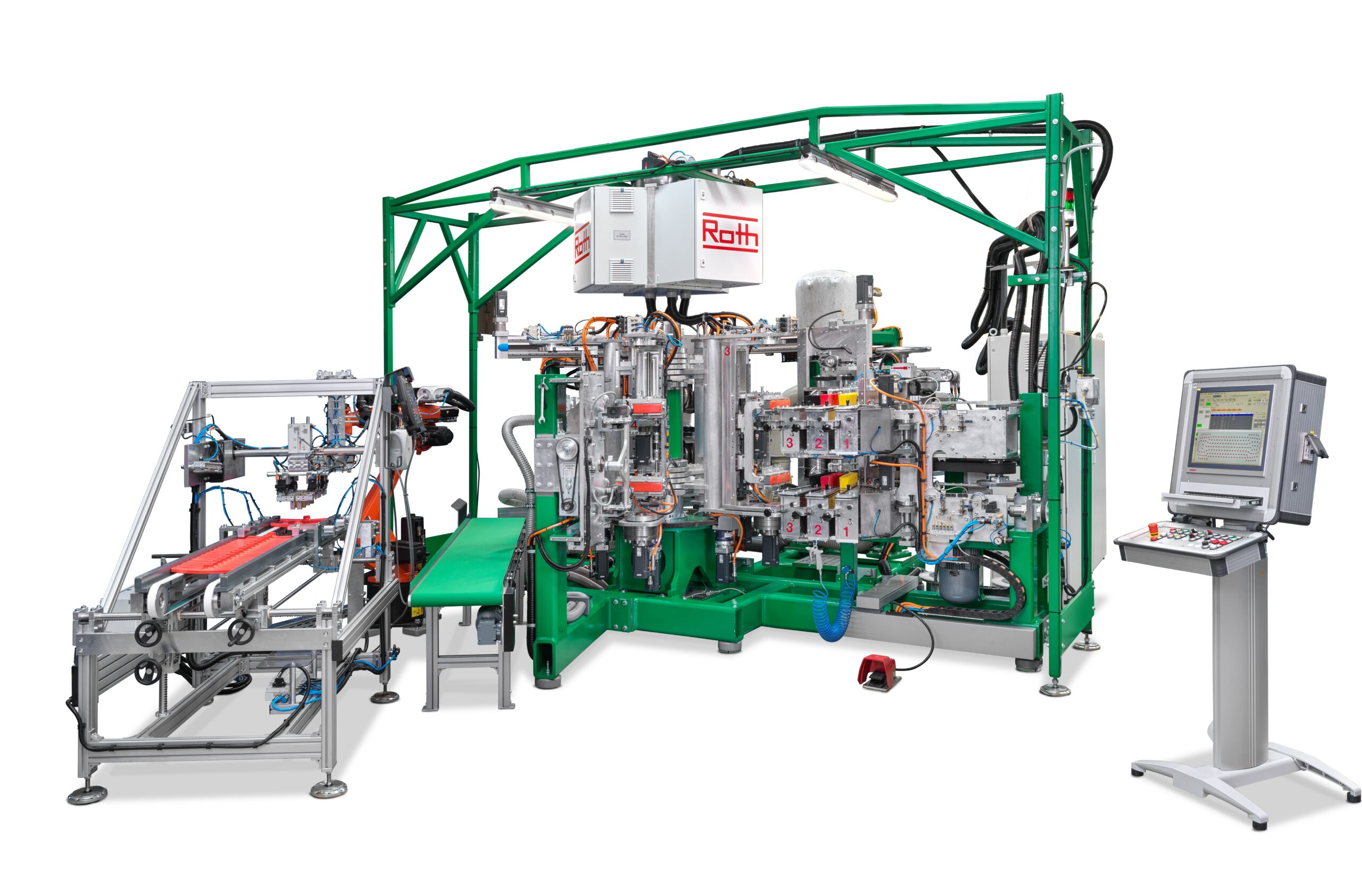

Roth Composite Machinery, headquartered in Burgwald, Germany, has announced the launch of its groundbreaking new machine for the brush industry. The new development from the innovation department includes several advantages for brush manufacturers. The fully automatic concept can be used to produce brushes that are completely different in terms of length, geometry and material — without the need for time-consuming retooling. The end result is a machine that offers reduced set-up times, higher output, and unparalleled flexibility in production.

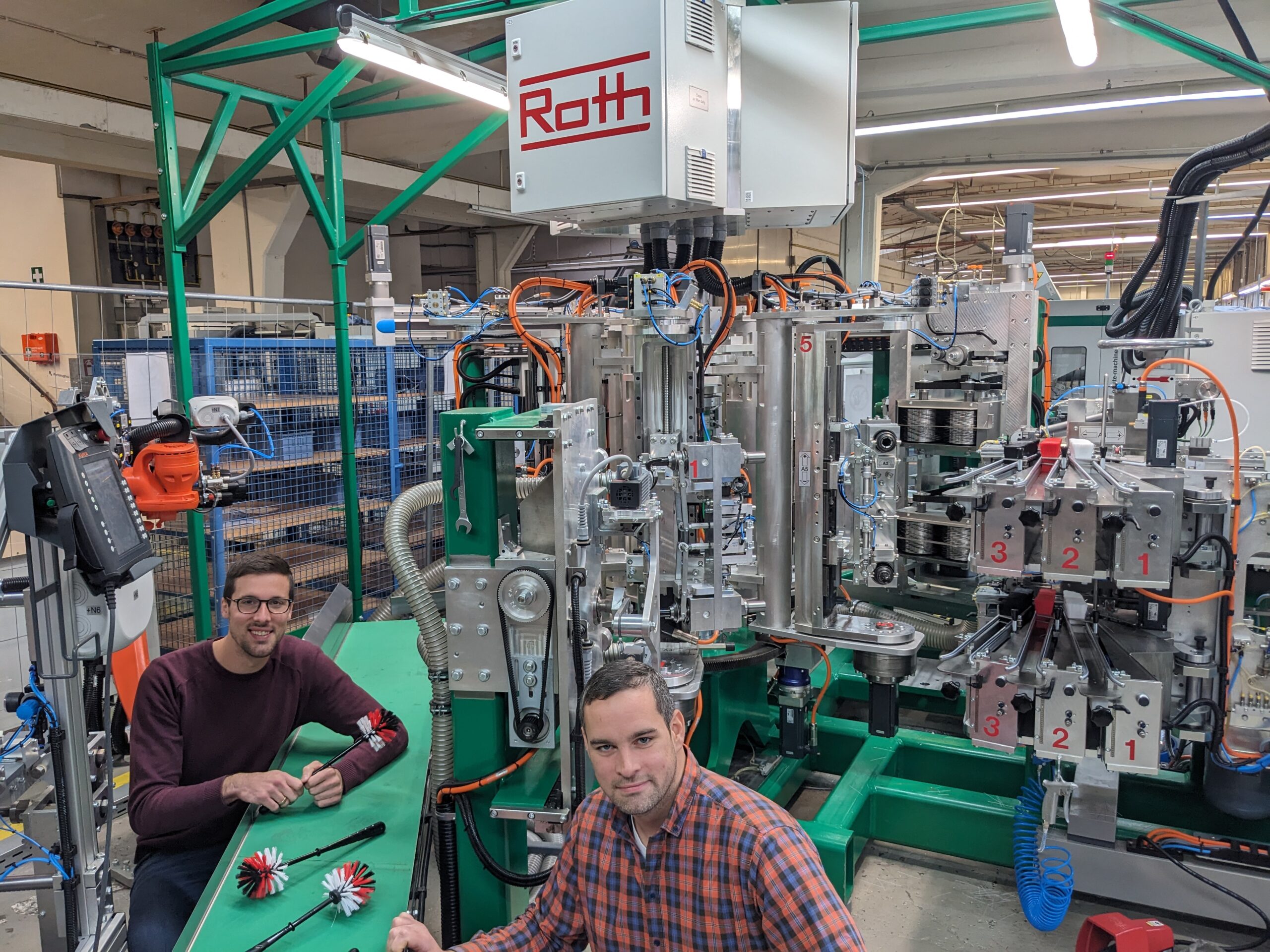

“During development, our main focus was on speed, flexibility and efficiency,” says Dennis Brückner, responsible for the Burgwald plant at Roth Composite Machinery. Thomas Halbrucker, sales engineer, says, “The machine concept fulfills the requirements of flexible mass production and meets our high standards of quality and sustainability.”

Machine concept integrates all work steps

The new brush-filling carousel features two filling tools and works according to the twin principle. With five electronic axes and the interchangeable carrier transfer design, the high-performance carousel machine can pick up brush bodies made of all common materials (such as plastic or wood) at extremely high speed, drill holes between 1.8 and 8.5 millimeters in diameter and fill them with the corresponding bristles. Finishing processes such as splicing the bristles, cleaning and even labeling or embossing the brush body are also fully automated. A shearing unit has been integrated for the production of toilet brushes, which can simply be called in if required.

Speed, speed

The speed offered by the new machine is also impressive. Each filling tool can produce 610 bundles per minute, meaning that the new machine can produce a total of 1220 bundles per minute. The innovative “Roth Flying Cabinet” system also ensures speed. The high-performance carousel rotates permanently in one direction, thus guaranteeing continuous operation without the carousel having to turn forward and backward. “This new process has several advantages,” says Halbrucker. “The maintenance effort is almost zero, which means that the machine has even less downtime. In addition, the ‘Roth Flying Cabinet’ is even less susceptible to external influences such as vibration or dirt.”

As an added bonus, the machine consumes less energy thanks to its very even operation. Manufacturers of household or industrial brushes can therefore significantly reduce their production costs with the new machine from Roth Composite Machinery with higher output quantity, shorter set-up times, lower maintenance requirements and energy-saving operation.

Energy-saving and completely CO2-friendly production in Burgwald

In line with the Roth companies’ aspirations, sustainability took center stage in the development of the new high-performance carousel. It is not only the operating principle of the machine that saves energy, but also the production of the new machine also takes a sustainable approach. The system was developed entirely at the Burgwald site and manufactured using 100 percent green electricity. No long transport routes are or were necessary to manufacture the new machine and only solvent-free paints are used.

Most importantly though, the machine scores points for durability and longevity. “We guarantee 25 years of spare parts availability,” says Brückner.

Learn more about Roth Composite Machinery at www.roth-composite-machinery.com.