Roth Company Celebrates 100th Year

250 Guests Participate in 100-Year Celebration

Roth Composite Machinery in Burgwald, Germany, is looking back on its company history of 100 years. The subsidiary of Roth Industries, Dautphetal, paid tribute to this event during an anniversary celebration. Business partners, current and former employees with their families, members of the Chamber of Industry and Commerce as well as political representatives participated in the event on September 13, 2019.

Manfred Roth welcomed the guests and expressed his gratitude to the employees for their engagement on behalf of the Roth family. “Our traditional company in Burgwald is known as Schlesinger Maschinenbau GmbH,” said Roth. “Since 1977 it belongs to the family-owned company Roth. The takeover was the first step into the sector of capital goods for us. Today, we can look back on a success story of 100 years. This is owed to our employees. On behalf of the management of Roth Industries and my family, I would like to thank the entire workforce for the tremendous commitment and loyalty.”

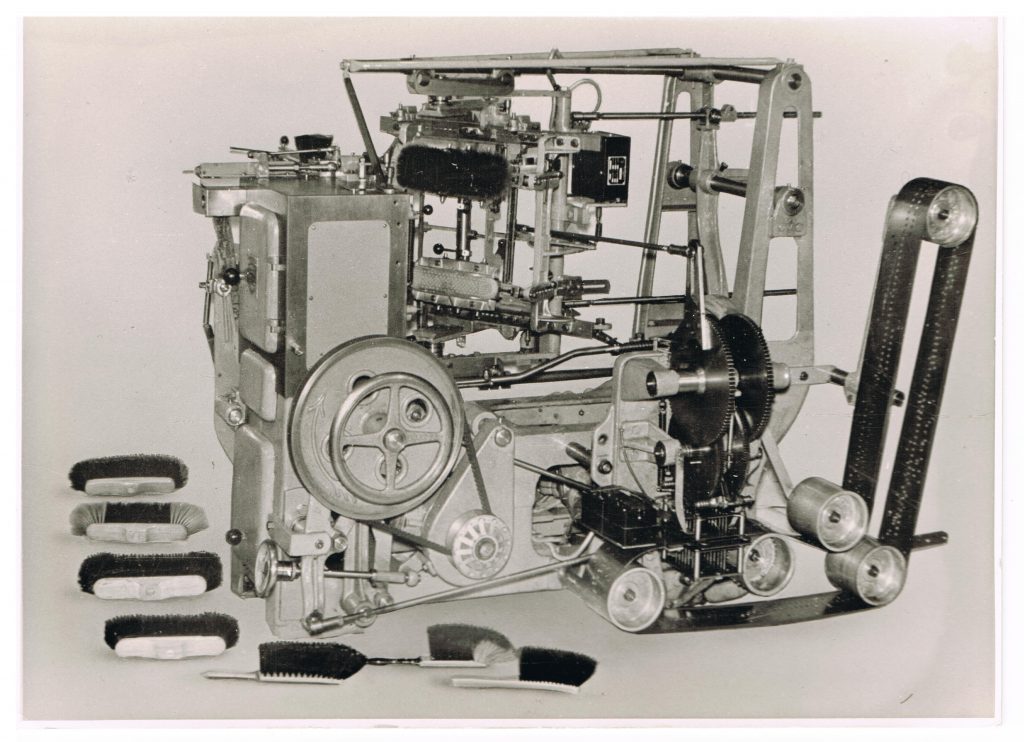

Since the merger with EHA Composite Machinery in 2016, the expert in the machine construction sector trades under the name Roth Composite Machinery. At the Burgwald location, the company is developing and manufacturing production machinery for the brush and broom industries as well as pleating machines for the filter production. The portfolio of Roth Composite Machinery also includes coating and Prepreg lines as well as machinery for the manufacture of light-weight components by using the filament winding process. In this field, the company is a world market leader.

International Breakthrough With Carrousel Machine

During the anniversary celebration, managing directors Alfred Kajewski and Dr. Andreas Reimann, and highlighted the key points of the company’s history. It traces back to the company start-up by Friedrich Schlesinger in the Saxon town of Schönheide in 1919. Originally, the manufacturer was focused on manual punching machines and multi-spindle drilling machines. In 1930, Schlesinger developed the first semi-automatic machine for realizing a simultaneous process of working steps drilling and filling necessary for fastening the bristle bundles. Ten years later, the company implemented the patented pattern band control for the fully automated manufacture of brushes. In 1951, Schlesinger moved to Burgwald, Industriehof. With the invention of the first fully automated carrousel machine in 1960, the company had its first international breakthrough.

During the third year after the take over by Roth, a key innovation for the future of the company with electronic position control. Furthermore, the company achieved larger market successes with new production lines for special applications, such as the first four-tool carrousel transfer machine for household brushes as well as a machine for the manufacture of car cleaning brushes.

In recent years, the company has been expanding its expertise on the international level with powerful drive elements that are feature energy savings with the introduction of a highly efficient production process. The new technology called “RoAn” is characterized by high flexibility and production speed. With those innovations, Roth Composite Machinery has joined world leaders in the industry for brush-making machines.

In 2011, the company started the extension of the product program for pleating lines. By using these machines, paper and plastic composite webs for air and hydraulic filters are prefabricated. Within a period of just five years, three types of knife pleating machines, a rotary pleating machine, production lines for the lateral adhesion of filters as well as mini-pleat systems have been developed and successfully introduced into the market. Today, the company belongs to the globally active and reputable manufacturers of special machinery in the industries for brushes, brooms and filters.

Synergies in Mechanical Engineering Strengthen the Market Positions

Since the merger with Roth Composite Machinery, the company relies on about 125 specialists and can optimally use synergies in the mechanical engineering of the Roth corporate group to strengthen market positions. About 45 employees are working at the location in Burgwald. The machines for brushes and brooms as well as the pleating equipment became substantial pillars for the company with promising growth prospects.

Alfred Kajewski says, “In the segment Pleating Machines, we see a great market potential which we intend to open up more intensively. We will further extend our engineering expertise towards hydraulics in the future. Currently, we are producing a demonstration machine for hydraulic applications in high-pressure ranges.“

Varied Program for the Occasion of the Anniversary

Manfred Roth handed a jubilee plaque to the Managing Directors Alfred Kajewski and Dr. Andreas Reimann as well as the chairman of the works committee, Uwe Cronau, on behalf of Roth Industries and his family. During the anniversary celebration, the company’s appreciation was noted by Dr. Peter Sacher, representative of the Chamber of Industry and Commerce Kassel-Marburg as well as Werner Fugmann, member of the local council of Burgwald. A varied program awaited around 250 guests, including company tours and machine demonstrations as well as games for both old and young attendees.

Historical Milestones

1919

-Friedrich Schlesinger has found the company in Schönheide/Erzgebirge

1930

-First semi-automatic brush-making machine

1940

-First machine with pattern band control

1951

-Relocation of the production and resettlement to Burgwald-Industriehof

1960

-Development of a fully automated 1-tool carrousel machine

1977

-Takeover of the company Friedrich Schlesinger by Roth Industries GmbH & Co. KG

1979

-First use of electronic positioning controls

1994

-First 4-tool carrousel transfer machine

2010

-Development of a new filling tool for the brush-making machines: RoAn technology

2011

-Establishment of a second machine division: Knife Pleating Machines

-Deepening of the cooperation with EHA Composite Machinery GmbH for realizing synergy effects as regards procurement and development

2012

-Development and prototype construction of a servo motor-driven knife pleating machine in cooperation with EHA Composite Machinery

2013

-Strengthening of the development and design processes

2014

-Development of a fully automated brush-making machine with integrated high-speed robot (Tripod)

-Introduction of the ERP system SAP/R3 EEC

-Expansion of the sales management system, regional sales enhencement as well as expansion of the sales representations

2015

-Development of a pleating line with rotary embossing rollers for large-scale pleating production plants

2016

-Merger with EHA Composite Machinery to Roth Composite Machinery GmbH

-Realization of the one-cable technology for shorter installation times and more effective set-up times for customers

2017

-Implementation of an e-editing system for the machine documentations and the drawing up of up-to-date instruction manuals

-Modernization and restructuring of the production and assembly procedures according to material flow principles

-Development of the world’s most powerful brush-making machine realizing a stroke of 350 mm for the manufacture of roller, disk and strip brushes

2018

-Advancement of the controlling software and simplification of the programming as well as operating interfaces for brush-making machines

2019

-100th anniversary

Learn more about Roth Composite Machinery at www.roth-industries.de.