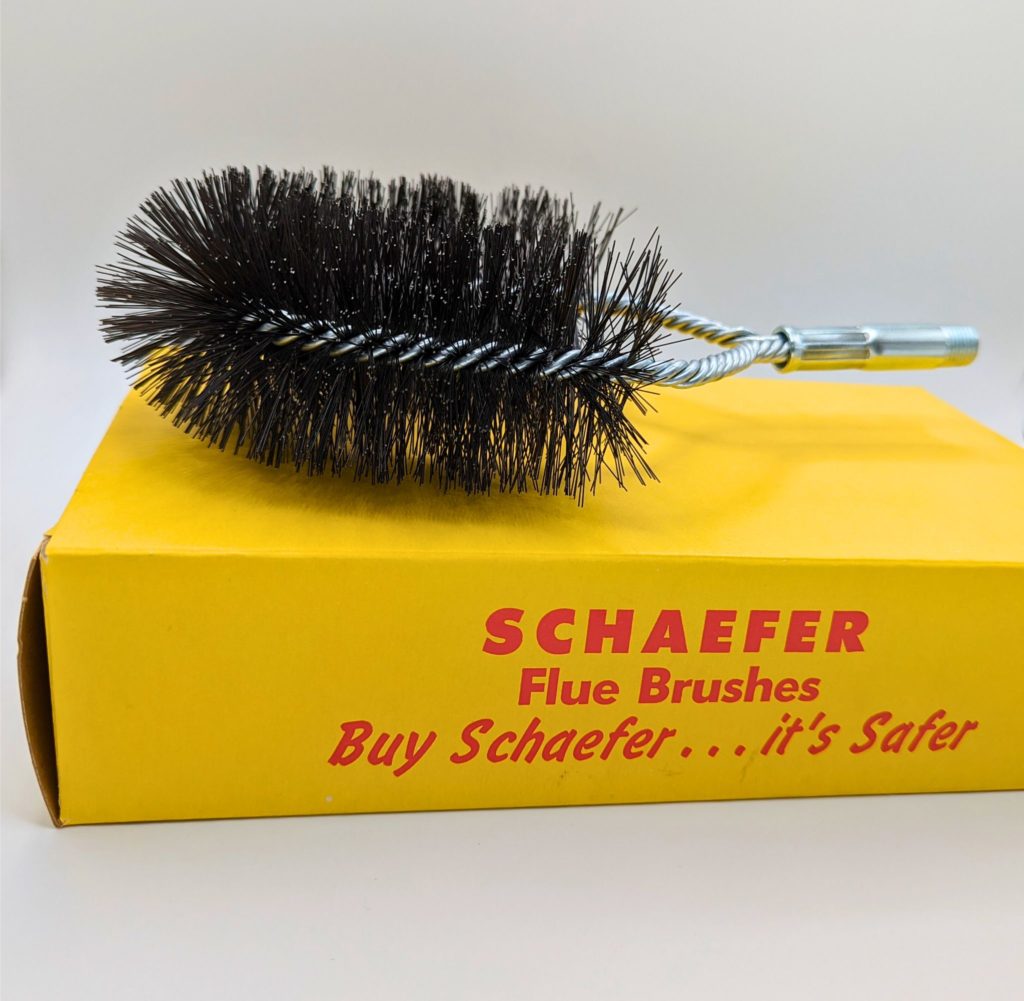

Schaefer Brush: Building Trust With Customers

President and CEO Gonzalo Martinez Offers Insights on the Schaefer Brush Approach

By Bob Lawrence

Talk about a legacy in the brush industry, this company undeniably has one for sure, including unique ownership. Founded in 1904 in Milwaukee, Wisconsin, Schaefer Brush was a family-owned and operated business until nine years ago when it was purchased by Milwaukee-based Blackthorne Partners, a private investment firm. At the time of the sale in 2015, then-company President Harold Schaefer said, “Our family spent 110 years developing and nurturing Schaefer Brush Manufacturing, so when it came time to sell the business we wanted buyers who would respect that legacy and Blackthorne Partners offered us just that.”

In 2019, Blackthorne also purchased E. Gornell & Sons, a now 132-year-old Chicago industrial brush manufacturer, and streamlined operations by bringing it under Schaefer’s management. “The purchase of Gornell,” President and Chief Executive Officer Gonzalo Martinez says, “has enabled Schaefer to provide customers with a more complete product line of industrial and maintenance brushes. Design capability, manufacturing technology and customer service have been improved through the synergy of bringing these two

companies together.”

As a result of the merger, Martinez is president and chief executive officer of both companies that then began sharing the same Waukesha-based administrative team inclusive of customer service, sales, marketing, accounting and engineering. “The team goes to Gornell in groups a few times a week or as needed to work more closely with the production team there,” he says.

His leadership role with Schaefer began on December 1, 2021, after more than 20 years of experience in sales and marketing, strategic planning, operations and business development. Prior to taking over at Schaefer, he was vice president of Pferd, Inc.’s North American headquarters in Milwaukee.

Asked why he took the position at Schaefer, he says, “Taking the reins as CEO and President at Schaefer and Gornell Brush was more than a career move for me — it was a deliberate choice fueled by the company’s exceptional commitment to creating standout customer experiences. Having dedicated my professional journey to customer-centric roles, the opportunity to lead an organization that places such a premium on customer satisfaction and enduring relationships resonated deeply with me.”

What energizes him about Schaefer and Gornell is, “Their relentless dedication to not just meeting but exceeding customer expectations. This aligns seamlessly with my vision for the company, and as CEO, I am eager to guide a team that shares this commitment to go the extra mile for our customers.”

Building Trust With Local Sourcing

In discussing the company’s emphasis on the fact that its brush products are manufactured in the U.S., Martinez says, “Emphasizing Made in America reflects our commitment to delivering high-quality products. We understand that our customers value durability and reliability, and manufacturing in the U.S. ensures rigorous quality standards, providing them with brushes that meet or exceed their expectations.” He adds, “Understanding that every customer may have unique requirements, manufacturing locally provides us with the flexibility to customize products. Whether it’s a specific brush design or a tailored solution, our customers can rely on us to meet their individual needs.”

According to Martinez, it’s not just about where the products are made but he says it is also about building trust. He says Schaefer aims to establish a strong and enduring relationship with our customers, assuring them that they are investing in a brand that values quality, integrity and customer satisfaction.

“Brush manufacturing often involves a degree of customization based on specific client needs, industry requirements and quality standards,” he says. “Companies emphasizing customization and specialized brushes may find value in local manufacturing where they can closely collaborate with clients and respond quickly to changing demands. Brushes are precision tools and maintaining consistent quality is crucial. Schaefer Brush prioritizes domestic production to have more direct oversight and control over the manufacturing processes, ensuring adherence to strict quality standards.”

Specialization is Key

Serving a diverse clientele, Schaefer’s sales footprint extends both within North America and worldwide with around 80 percent, dedicated to the American market according to Martinez. Approximately 20 percent of sales are global with Europe and Asia being their biggest international markets.

Schaefer Brush’s products are designed to solve a wide range of cleaning, finishing and surface preparation challenges across a range of industries. Specializing in industrial brush manufacturing, the company excels in the innovation and enhancement of automated cleaning processes. This applies equally to its bespoke custom brush manufacturing division, which collaborates with companies to design and produce innovative cleaning solutions.

The largest share of the company’s production is OEM, (automotive, aerospace), followed by metalworking, power generation and HVAC due to its expertise and specialization in those areas.

“Specialization allows us to understand the unique challenges and requirements of each market. OEMs, power generation and HVAC are industries with substantial industrial applications. Brushes play crucial roles in these sectors for tasks such as cleaning, polishing, deburring and ensuring the efficient functioning of machinery and equipment,” says Martinez. “Those industries are core components of many economies, and there is a consistent demand for products and components that support their operations. By focusing on these markets, Schaefer Brush aligns with sectors that have ongoing and essential needs for their products. By specializing in specific markets, Schaefer Brush has established long-term relationships with clients in OEM, metalworking, power generation and HVAC. Building enduring partnerships in these sectors contributes to consistent business and customer loyalty.”

Competitive Industrial Brush Sector

Schaefer and other industrial brush manufacturers are engaged in a highly competitive market because their products are used across a wide range of applications and industries including manufacturing, metalworking, automotive, aerospace and more. As Martinez puts it, “The diversity of applications often leads to a competitive landscape as companies strive to serve specialized needs within each sector. The demand for customized brushes tailored to specific industrial processes and applications drives competition. Advancements in brush materials, manufacturing technologies and design contribute to competition. Price sensitivity, regulatory compliance, quality and durability all add to a competitive industry.”

Amid this competition, he says what makes Schaefer stand out is, “Customization and specialization,” explaining that Schaefer and Gornell offer, “customizable solutions that cater to specific industry needs and applications. We understand the unique requirements of different sectors and provide tailored brush solutions. We provide brushes that withstand harsh industrial conditions and deliver consistent performance. While quality is crucial, offering competitive pricing and value-added services sets us apart from our competitors.”

Tackling Recent Challenges

Whether a manufacturer or consumer, inflation has had an impact, and in Schaefer’s case, Martinez identifies areas where inflation has impacted the company, primarily in the escalation of raw material costs, labor expenditures and operational expenses. Thus, he says, “Armed with data-driven insights, we swiftly transitioned to strategic cost management. The goal was clear — to optimize operational efficiency while mitigating the impact of inflation on our cost structures.”

As for supply chain issues, he initiated a comprehensive supply chain optimization program involving negotiations with suppliers, diversification of sourcing strategies and a relentless pursuit of operational excellence to mitigate disruptions and enhance resilience. Martinez adds, “A cornerstone of our strategy is in transparent communication with our valued customers. Open dialogue regarding necessary adjustments to product pricing and offerings became imperative.”

Additionally, he says, “Our focus lies on strategic investments in technology, process enhancements and initiatives that bolster our company against the prevailing economic currents.”

In manufacturing its industrial brushes Martinez says Schaefer uses a wide variety of high-quality raw materials with bristles made from various materials, including metals such as steel, stainless steel, bronze and brass and natural fibers such as hog hair, horsehair, or plant fibers, as well as synthetic materials like nylon, polypropylene or abrasive materials for specific applications.

Wires used in its brushes are made from steel, stainless steel, brass or other alloys depending on the required strength and corrosion resistance. The base or backing of the brushes is often made from materials such as wood, plastic or metal depending on the application and durability requirements. As for the costs for those raw materials, “Schaefer has experienced significant price increases affecting the majority if not all of the raw materials it buys,” according to Martinez.

Innovation and Customer Satisfaction

Regarding the company’s production output, Martinez says, “In a market where one-size-fits-all simply doesn’t cut it, our company takes pride in the fact that nearly 40 percent of our sales are customized products. This signifies our commitment to providing bespoke solutions that address the individualized needs of our clients. Whether it’s tailoring specifications to unique requirements or creating personalized designs, our emphasis on customization showcases our flexibility and responsiveness. This significant portion of our product offerings being custom underscores our dedication to innovation and customer satisfaction. It’s not just about meeting expectations; it’s about exceeding them by delivering products that are precisely aligned with the diverse preferences and specifications of our valued customers.”

Expansion Opportunities

Schaefer’s 70,000 sq. ft. facility housing offices and production is located on five acres in Waukesha, Wisconsin, affords plenty of room for growth, and that could very well happen as the company is actively considering expansion plans to further strengthen its position in the market to accommodate the evolving needs of the customers. Martinez says, “We are exploring opportunities to enhance both our office and production facilities, leveraging a growth-oriented approach to meet increased demand and capitalize on emerging market trends. The decision to expand is driven by a strategic vision for the future. We aim not only to meet the current demands of our customers but also to proactively position ourselves for sustained growth and market leadership.”

In Chicago, its Gornell production facility spans 30,000 square feet.

The Importance of Technology

Asked if Schaefer has reached the pinnacle in manufacturing its products and custom brush making, Martinez says the company believes, “The pursuit of excellence is a continuous journey. While we take pride in our current achievements and the quality of our products, we firmly believe in the importance of ongoing research and development.”

In Waukesha, the company has 40 employees and in Chicago, there are 30. Additionally, automation is employed at both facilities. “Embracing cutting-edge technologies is paramount for our company’s continued leadership in the brush industry,” says Martinez. “In our production processes, we have strategically integrated automation to enhance efficiency, precision and overall output. Our approach is to leverage automation where it brings the most value, allowing our skilled workforce to focus on tasks that require creativity, problem-solving and a human touch. This combination of automation and skilled labor ensures a harmonious synergy that optimizes production, maintains product quality and positions us as an industry leader in both innovation and craftsmanship.”

Recruiting and Labor

As for employee recruitment, he says it has been an issue affecting both facilities, but the situation in Waukesha has been more challenging due to very low local unemployment rates and a competitive manufacturing landscape. Given the importance of employee retention, Schaefer has implemented the following strategy:

- Ensure that compensation and benefits packages are competitive within the local market. This includes salary, healthcare, retirement plans, bonus programs, etc.

- Establish partnerships with local technical and vocational schools in Waukesha.

- Career Development Opportunities: Training programs, mentorship opportunities and support for continuous learning.

- Collaboration with local job placement services and staffing agencies specializing in the Waukesha region.

- Work-Life Balance: Focus on promoting a healthy work-life balance. Encourage reasonable working hours and avoid a culture of constant overtime. Implement flexible work arrangements and consider remote work options to accommodate diverse needs.

- Foster a positive and inclusive work environment to ensure that employees feel valued, respected and supported.

- Invest in leadership development programs. Ensure that employees feel aligned with the company’s values and mission.

As 2024 begins, so does Schaefer’s 119th year. Martinez says the following factors have contributed to the longevity of the company: adaptability and innovation, quality and reputation, a customer-centric approach, employee engagement and expertise, strategic leadership, strategic partnerships and collaborations and continuous improvement.

Learn more about Schaefer Brush at www.schaeferbrush.com and Gornell Brush at www.gornellbrush.com.