WÖHLER – Innovations Make It Possible

Regardless of the brush industry sector your business is focused on, one thing always prevails – the exceptional level of innovation. Whether it is strip brush, roll brush, power brush or twisted brush production, the possibilities are nearly endless. There is always an opportunity to look for new applications and uses. To date, this innovative force has been the driver for progress for entire industrial sectors.

The greatest hurdle in the brush industry lies in the development of new, innovative products. Growing demand calls not only for inventiveness, but also expertise in turning a good idea into a successful product. Many factors should be considered in making an item of use or a consumable from a prototype brush. Factors such as automated producibility and flexibility must be part of product development already at an early stage. With Wöhler, the brush industry has a partner from the outset with over 80 years of expertise in brush making.

The success of such cooperation can be seen in the latest machine developments by Wöhler together with brush producers.

New Possibilities In Strip Brush Production

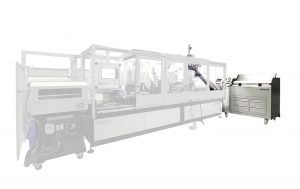

Progress does not stand still even for proven machinery like the strip brush machine Wöhler SBM 92. This is what made the latest update of the Wöhler SBM 92 possible. The new automatic bundle feeding consists of the bundle cutter Wöhler BC 760 and bundle feeding Wöhler BUD 300. Simpler, faster and more reliable were the demands for further development of the bundle feeding. The result was not only further increased process reliability, the upgrade also makes bundle lengths of up to 250 mm now possible. This opens new opportunities in expanding product portfolios and maximizing the potential of the strip brush machine.

Expanding Product Portfolios – Opening New Markets

With the goal of helping brush makers expand their product portfolios, Wöhler has turned strip brush production literally upside down. This is exactly what the newly developed strip brush finishing station Wöhler FSA 500 makes possible. The hanging processing of the strip brush allows finishing of short fill up to very long, soft fill in with considerably higher quality than was ever possible in standard processing of difficult fill materials to date. The finishing station Wöhler FSA 500 can be readily integrated to an existing production line, or alternatively operate in stand-alone mode.

Winding And Trimming Of Roll Brushes On A Single Machine

Winding of a strip brush into a roll brush directly inline is a key strength for the Wöhler WIBO winder. Now, trimming is also possible directly on the Wöhler WIBO. This has been made possible with the innovative combination of the Wöhler WIBO. winder and the Wöhler FS 930 trimmer, specially developed for the brush industry. Even contour trimming can be realized and this option saves a great deal of handling costs and makes the production of wound roll brushes even more flexible.

Always The Right Trimming Solution

The combination of Wöhler WIBO winder and Wöhler FS 930 trimmer is just one example of the many possibilities available with the modular construction system of Wöhler. The roll and disk brush trimming machine Wöhler TU 900 was developed based on the same concept. This trimming machine has a quick ROI and allows for trimming of large roll brushes up to 1 m in diameter and 5 m long, with a weight up to 1.5 t. Disc brushes can also be trimmed with a diameter of up to 1 m.

Wöhler offers a whole range of brush trimming machines – from manual and semi-automatic right up to fully automatic. There is the right solution for almost every requirement. Here again the modular construction system shows that individual solutions can be developed both quickly and economically.

Process Optimisation Is Generally Always Possible

An optional change-over magazine, now available as a module for the twist knot brush machine Wöhler ZVA 320, relieves the operator and ensures an easier process. Optical and acoustic signals help in making daily working life even more efficient.

Wöhler at Interbrush 2020

When Wöhler displays at Interbrush 2020 in Freiburg next year, there will be a number of innovative developments presented. Industry 4.0 will be a theme and for the first time, Wöhler will also show the “big” machines from the world of street sweeper brush machines. The Wöhler team will be at your service and is already looking forward to fascinating talks and new challenges to solve together. Be sure to plan a visit to Wöhler at the Interbrush fair.