WOMAtec: Wood Products Are On The Rise Again

All of these and many more wooden items can be produced on the WOMAtec copying shaper

Flexible production with the WOMAtec copy shaping machine

Where injection molding prevailed for the brush industry a few years ago, wood is on the rise again as it is now increasingly used as a renewable raw material. This trend is particularly noticeable in the household, cosmetic and oral hygiene sectors.

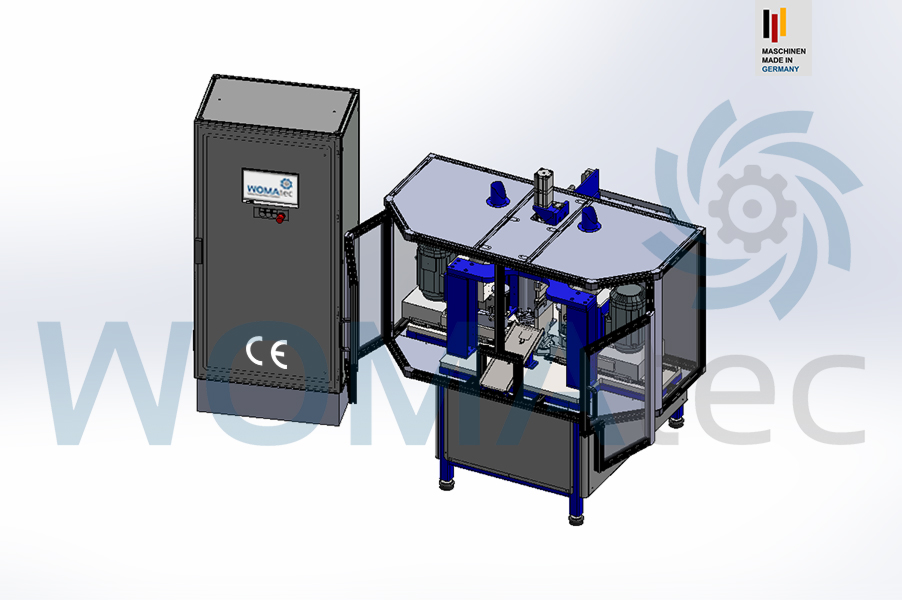

With the automatic copying shaper “ROTARY,” German machine builder WOMAtec has implemented the CNC-controlled manufacturing process for the first time and the result is optimization for both quality and efficiency. With an output of up to 10 pieces per minute (the multiple for batch processing), milling with a turntable is now also efficient for products that need to be manufactured in high batch sizes, like wooden toothbrushes, which are becoming more and more popular on the market. To meet that increasing demand, WOMAtec currently has four machines for shaping and drilling toothbrush handles in production.

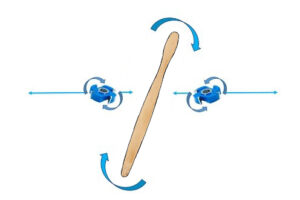

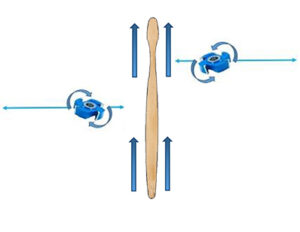

Thanks to solid construction and high-quality production, “ROTARY” is precise enough for delicate items, yet still offers extreme flexibility. A dxf drawing transferred via USB stick can be converted into the contour to be produced in seconds using the WOMAtec CNC control. Different contours, e.g. for different radii, can also be used for both cutters. With a speed of up to 12,000 rotations per minute, the milling cutters leave a perfect surface and, thanks to the rotating plate, never work against the wood fiber, making subsequent sanding unnecessary. And that is a key benefit, as a good smooth feel is particularly important for hair brushes, toothbrushes, knife handles, etc. In addition, all imaginable types of wood and bamboo can be processed and with various adjustment options for feed and milling speed, a flawless milling result is always ensured.

A CE-compliant solid housing ensures safety and protects the operator from dust and noise. The WOMAtec copying shaper is not only a pioneer in terms of safety, it also embodies the company philosophy of sustainability. Solid construction and the utilization of widely available spare parts is the standard approach for all WOMAtec machines. With a high level of vertical integration, the machines are almost 100% manufactured in-house and purchased parts come from well-known manufacturers such as Beckhoff, Festo or SEW. Plus, WOMAtec uses existing copying shapers from companies such as Hempel/Hemco, Boucherie (as well as brush drilling and filling machines) for overhauls and retrofits with new CNC controls, which saves on both resources and costs.

Learn more about WOMAtec at www.womatec.com.