ZAHORANSKY: Improved Output with ZMI 4.0, Z.LYNX 3 and Z.SAILFIN

Larger Quantities and More Operating Comfort

With its new ZMI 4.0 machine controls, ZAHORANSKY AG not only offers greater operator efficiency, but also significantly increases the output of twisted-in-wire brushes.

Running on new software, the Z.SAILFIN now boasts an output increase of 12 percent in the production of mascara, medical and interdental brushes. Instead of 85 brushes, the machine can now produce up to 95 brushes per minute with more precise controls of the servo motors. The output of the completely redeveloped Z.LYNX 3 for the production of twisted-in-wire brushes increases almost two-fold, depending on the brush model – from four to up to 7.5 brushes per minute (an increase of 85 percent).

Robert Dous, Director Sales & Marketing of ZAHORANSKY AG, explains, “After Interbrush was postponed, we are now even more delighted to finally present our new machines, systems and technologies to the market and to our customers. The new ZMI 4.0, reworked Z.LYNX 3, as well as greater output figures of the Z.SAILFIN are only a first taste of what’s to come. We will introduce more innovations in the coming weeks and months.”

ZMI 4.0: Smart Machine Controls

Reprogrammed from the ground up, the new ZAHORANSKY Machine Intelligence 4.0 (ZMI) features new upgrades at the operator panel with controls consistently geared toward the requirements of the operator. The modern and intuitive touch controls with clear icons and wizards reduce training effort all down the line, with programming for specified motion sequences of the machine presented in predefined building blocks. As an example, test users managed to reduce the time to program trimming profiles by five to 10 minutes, with the time required to put the machine into operation reduced accordingly. The control center also benefits from greater transparency: production figures are visualized and can be tracked over set periods of time.

ZMI 4.0 takes processes that logically follow each other into account, minimizing operating errors. If anything is unclear during operation or if questions arise, “Help me” wizards suggest suitable solutions. The integrated service mode makes it easier to request international support and overcoming language barriers. ZMI 4.0 utilizes a unique ID number stored in every field of the display (for example, in the settings of the filament feed). The ID only needs to be mentioned when making an inquiry, for easier identification of faults which speeds up the support process. Besides the new operating concept, the ZMI 4.0 makes it possible to achieve quicker and more precise control times for the servo motors on machines such as the Z.SAILFIN and Z.LYNX 3. They run more quietly and quickly, which is reflected in higher outputs.

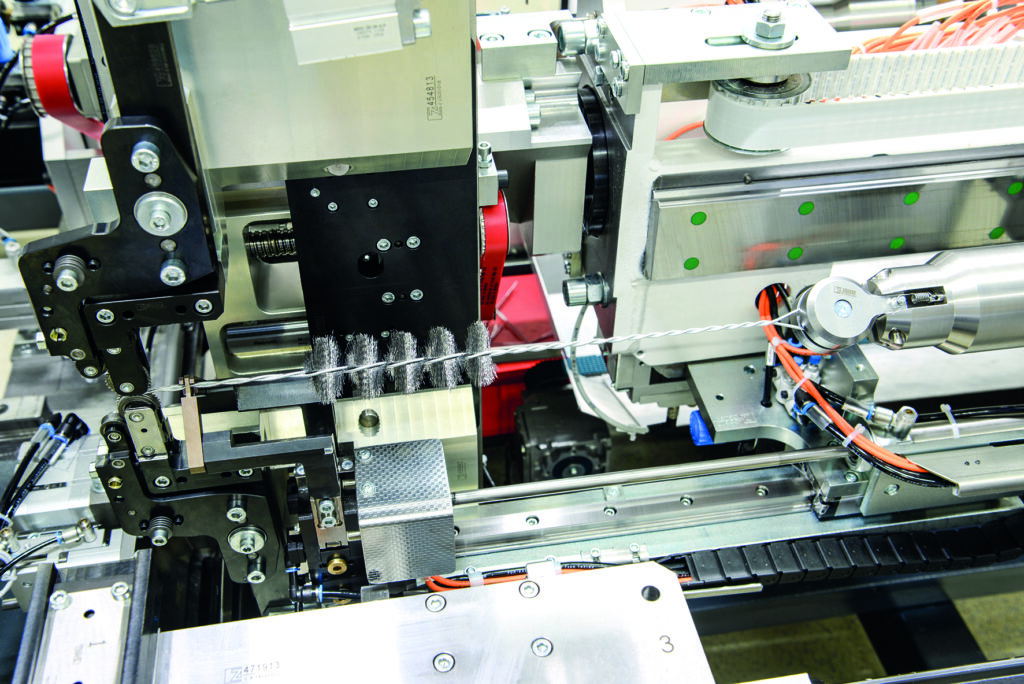

Z.LYNX 3: Redeveloped for Greater Performance

Z.LYNX 3, the specialist in the production of twisted-in-wire brushes, has been redeveloped from the ground up. The machine concept was above all reworked to allow for conversion to parallelized production. Up to now, one brush was produced completely before producing the next brush. Now, half a brush is produced at one station, and further processing or finishing takes place at the next station. Output increases by up to 85 percent, depending on the brush model, with an increase of four to 7.5 brushes per minute. This is also largely attributable to the gentler motor controls of the ZMI 4.0. Even with these greater performance specifications, the machine can still process wire core diameters of one to four mm, but much quicker.

Learn more about ZAHORANSKY at www.zahoransky.com.